What Size Fuel Filter Do I Need

How Fuel Filter Micron Size Matters in Diesel CFPP

How Filter Micron Size Matters in Diesel fuel CFPP (Common cold Filter Plug Point)

When winter is upon united states of america, we always wish we were more than prepared. This inquiry commodity is written to help you lot understand the vital function of diesel fuel filters and specifically their rated micron size and how this affects farthermost common cold weather performance. This is informational and as our disclaimer states below… always consult with the engine manufacturer and use a quality lab for fuel and fuel filter testing. Fuel & Friction does not warranty or guarantee the 3rd political party provided information contained herein and is for informational purposes only.

With all the preparation and precautions that are taken for your diesel powered truck or structure equipment… quite frequently, a weather system will bring in a cold front and severely cold freezing temperatures. During these times you lot may experience a diesel fuel engine not-start condition or freeze up of a diesel fuel engine. We're non talking about the anti-freeze either, this has to do with fuel and fuel filters for the purposes of this article.

Water Contamination

Is the nearly common grade of contaminant. Information technology may be introduced into the fuel supply during warm periods when wet forms in the tanks and condenses on the cold metal walls of the fuel storage tanks or from poor housekeeping practices. Water tin can seriously impairment the injector components and can contribute in the reduction of lubricity of the fuel which can impairment components that work with shut tolerance – for case the fuel pump assemblies.

Water Contamination Remedy

H2o can be removed from the diesel by using in-line water separating filters or devices. Your best and easiest method of prevention is to purchase fuel from reputable suppliers that can provide high quality fuel on a consistent basis. Also keeping the tank as full equally possible at all times prevents condensation. Bottom line: Be sure to change your fuel filters more often in the winter months. H2o is a filters worst nightmare.

Wax Contagion

Wax is a source of energy in fuel but needs to exist controlled in cold weather operations. Diesel fuel contains paraffin which provides the engine with proper lubrication. Nevertheless, cold temperatures that can make fuel go below it'south deject point, which results in wax precipitation and filter plugging .

Wax Contagion Remedy

To foreclose wax formation the cloud point of fuel must exist at least +12° Celsius (+22°F) below the lowest exterior temperature. Fuel suppliers blend diesel fuel based on local anticipated cold conditions conditions, just this method is slowly becoming obsolete. Using a Fuel Conditioner such as CleanBoost® Sno-True cat™ helps shield your fuel from wax crystals forming. It's piece of cake to use, fast to dose and cheap to run. This makes it one of the best and virtually efficient winter diesel fuel dosing choices around.

We reached out to Combustion Technologies for additional insight on filter micron sizes and the furnishings since 2007.

Disclaimer: The following information is provided for reference just on an as-is basis, with no warranty limited or implied as to the correctness or viability for your item situation or awarding. Be certain to test your fuels with a quality lab for analysis and check with your equipment or vehicle manufacturer before applying or installing whatsoever non-factory approved filters. Fuel & Friction does not recommend or accept whatsoever liability as to how yous may use this information.

We have news for yous. Diesel filters are non all created equal. They all have unlike filtering medias and micron ratings for a reason. This reason has to practise with their specific application for which they were originally designed for. Since 2007, ULSD (Ultra Low Sulfur Diesel fuel) fuels have get the standard for us here in the United States and other regions.

The Challenge

ULSD fuel does bring with it, new challenges when it comes to lubricity and overall quality. Testing fuels is something that you should consider for your fleet if yous're at all serious virtually reducing maintenance costs and keeping trucks and equipment running at peak efficiency. Testing and performance at ultra cold temperatures is another story entirely.

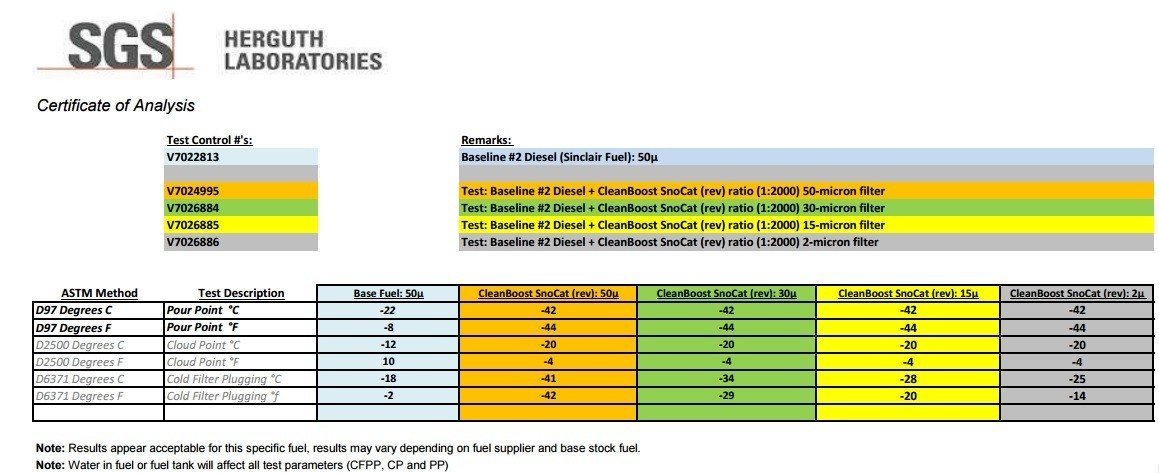

With the help of SGS / Herguth Labs, testing was performed comparing filter medias and micron ratings to see the departure betwixt iii types of filters:

-Baldwin Fuel Filter – 30 micron rating

-Wix/Napa Fuel Filter – 15 micron rating

-Cat/Donaldson Fuel Filter – 2 micron rating

The results are intriguing. The Cascade Point was never affected, even so the Cold Filter Plugging Point displayed a big drop in temperature functioning depending on micron rating of the filter. Click on image beneath to view its entirety:

Cascade Point Test with Different Filter brands and Micron Sizes

"Cold Filter Plug Betoken (CFPP) ASTM D6371 – This test is a more complicated procedure which involves using a vacuum to draw a 20cc fuel sample through a 45 to 50-micron screen inside a threescore second time menstruation. Up until 2007, the introduction of ULSD (Ultra Depression Sulfur Diesel), many if not most operators used CFPP to provide a reference temperature for cold weather operability with diesel fuels. This is nonetheless a complicated and imperfect examination. As mentioned to a higher place, CFPP uses a vacuum to draw a sample of the fuel through a 45 to 50- micron screen within a given time. The point at which the sample fails to go through the screen in 60 seconds is the CFPP. The principal effect is that up until 2007, most fuel filters used by operators were a xxx-micron rated media. Todays OEM Engine Manufactures recommend using a two to 10-micron filter to help protect direct injection applications as well as keep the fuel system cleaner due to ULSD quality fuels. The significant difference of 10 microns and 45 microns acquired a disparity between the test and real world operations. Even so, many in the manufacture felt that this differential was consistent and provided a reliable guide for cold atmospheric condition operability. For example, if testing showed you had a CFPP of -24°F, you could feel reasonably confident that yous could operate to -10°F using a x micron fuel filter for the engine." – (source Brett Winberg – Combustion Technologies USA.)"

In other words, due to ULSD quality fuels, near engine manufacturers today recommend using a two to 10 micron filter. The test showed that CleanBoost® Sno-Cat™ has a tremendous consequence on Cascade Betoken, Cloud Betoken and Cold Filter Plugging Point performance at the different filter micron ratings. All testing above was washed at a mix ratio of 1:2,000 which took a Pour Bespeak performance from -eight° Fahrenheit to -44° Fahrenheit. The Cloud Bespeak performance from 10° Fahrenheit to -4° Fahrenheit… and finally,the Cold Filter Plug Signal performance from -two° Fahrenheit to -29° Fahrenheit (Baldwin filter), -20° Fahrenheit (Wix/Napa filter) and -xiv° Fahrenheit (Cat/Donaldson filter). Over again, this is based on using CleanBoost® Sno-Cat™ at a mix ratio of one:2,000, which equates to 16 oz of CleanBoost® Sno-Cat™ to 250 gallons of ULSD diesel fuel.

When it comes to severe cold weather snaps in your expanse, you may desire to consider this information vital to your truck or equipment armada to continue information technology starting and running in these extreme temperatures.

What Size Fuel Filter Do I Need,

Source: https://fuelandfriction.com/trucking-pro/how-fuel-filter-micron-size-matters-in-diesel-cfpp/

Posted by: elliottlizintacer1944.blogspot.com

0 Response to "What Size Fuel Filter Do I Need"

Post a Comment